- Home Page

- Company Profile

-

Our Products

- Pharmaceutical Machine

- Packaging Machine

- Machine Part

- Homogenizer Mixing

- Romaco Machine Change Part

- Romaco Machine Feeding Channel

- Pvc Alu Blister Machine Change Parts

- Blister Packaging Machine Change Parts

- Alu-Alu Feeding Channel

- 240 Blister Machine Change Parts

- Counter Sealing Roller

- Blister Feeding Channel

- Capsule Filling Machine Change Part

- PVC Alu Blister Machine Change Part

- BQS Machine Change Parts

- Automatic Capsule Filling Machine Change Parts

- Copper Sealing Plate

- Strip Mc Change Parts

- Pharmaceutical Blender

- Capsule Printing Machine

- Industrial Water Chiller

- Pharma Equipments

- Punching Tool

- Cartoning Machine

- Vacuum Pump

- Contact Us

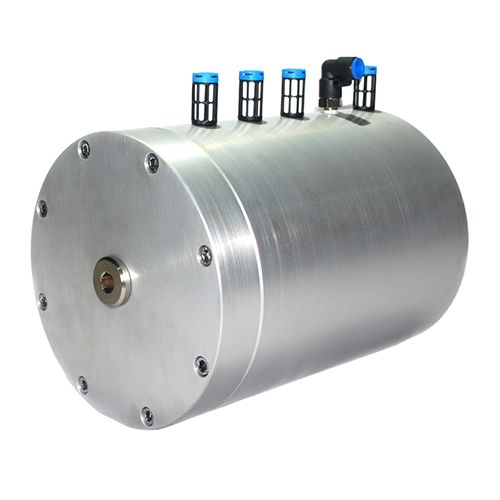

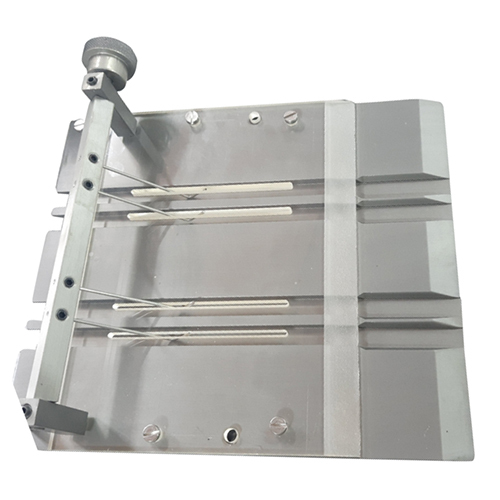

Blister Packaging Machine Change Parts

Product Details:

- Noise Level Low noise operation

- Diameter As required by machine model

- Motor Power Based on machine specifications

- Lubricating System Manual/Automatic (as per machine design)

- Surface Finish Smooth, Corrosion Resistant

- Size Custom-fit for blister machines

- Capacity Compatible with high-speed blister packaging

- Click to View more

X

Blister Packaging Machine Change Parts Price And Quantity

- 1 Unit

- Good thermal stability for packaging processes

- Surface Hardened for Longevity

- Suited for Alu-Alu & PVC Blister Packing Machines

- Standard Export Quality Packaging to avoid damage

- Low maintenance requirement

- Fully customizable to client drawings/specs

- High resistance to rust

Blister Packaging Machine Change Parts Product Specifications

- As per design

- As per part design

- Magnetism

- 220-240 V, 50/60 Hz

- Stainless Steel / Iron

- Machine Parts

- Mechanical/Electric

- Precision engineered, Durable, Easy installation

- Blister Packaging Machine, Pharmaceutical & FMCG Packaging

- Electric

- Painted

- Based on machine specifications

- As Per Availability

- As required by machine model

- Low noise operation

- As per drawing or customization

- Customizable as per machine requirement

- Adjustable as per machine specifications

- Compatible with high-speed blister packaging

- Custom-fit for blister machines

- Smooth, Corrosion Resistant

- Manual/Automatic (as per machine design)

- Good thermal stability for packaging processes

- Surface Hardened for Longevity

- Suited for Alu-Alu & PVC Blister Packing Machines

- Standard Export Quality Packaging to avoid damage

- Low maintenance requirement

- Fully customizable to client drawings/specs

- High resistance to rust

Blister Packaging Machine Change Parts Trade Information

- 100 Unit Per Month

- 10 Days

- All India

Product Description

Optimize your blister packaging machine with our Change Parts. Engineered for seamless integration and precision, these components ensure smooth and efficient operation. Crafted from high-quality materials, each part is designed for durability, reducing downtime and maximizing productivity. With easy installation and compatibility, upgrading your machine is hassle-free. Trust in our expertise to enhance your packaging processes, delivering reliable performance and consistent results. Elevate your production efficiency with our premium change parts, tailored to meet the demands of your packaging requirements."

Engineered for Compatibility and Precision

Our change parts seamlessly integrate with both Alu-Alu and PVC blister packing machines, accommodating a wide range of machine models. Each component is custom-fit according to your provided technical drawings or specifications, ensuring superior compatibility and consistent performance. Their versatile design makes them ideal for pharmaceutical and FMCG packaging industries, adapting flawlessly to various manufacturing requirements.

Superior Durability and Maintenance Efficiency

These parts are crafted with a surface-hardened finish and a robust corrosion-resistant layer, making them exceptionally durable in challenging operational environments. The materials and surface treatments provide high resistance to rust and thermal wear, contributing to a longer lifecycle with minimal maintenance. Their smooth finish further aids cleaning and reduces operational friction.

FAQs of Blister Packaging Machine Change Parts:

Q: How are the change parts compatible with different blister packaging machines?

A: The change parts are designed to fit both Alu-Alu and PVC blister packing machines. They are fully customizable based on your machines drawings or specifications, ensuring exact compatibility regardless of brand, model, or application requirement.Q: What materials are used for these blister packaging machine change parts?

A: We manufacture the parts from high-grade stainless steel or iron. Both materials offer excellent surface hardness and corrosion resistance to ensure longevity and stable performance, even under continuous exposure to heat and moisture.Q: When should I consider replacing my blister packing machines change parts?

A: Replacement is recommended if you notice reduced packaging efficiency, excessive noise, visible wear, or inconsistent sealing. Our parts durability and wear-resistance mean youll benefit from extended intervals between replacements.Q: Where can these change parts be used?

A: They are suitable for a wide range of blister packaging machines, commonly employed in pharmaceutical and FMCG packaging industries. The parts can be installed in machines located in various manufacturing and packaging facilities worldwide.Q: How does the maintenance process for these parts work?

A: The change parts require minimal maintenance due to their surface-hardened finish and corrosion resistance. Depending on machine design, lubricating your parts can be manual or automatic, and routine cleaning is simplified by the smooth surface finish.Q: What are the benefits of customizing the change parts?

A: Customizing the change parts ensures a perfect fit and optimal performance in your specific blister packaging machine model. This reduces downtime, improves packaging quality, and extends the overall service life of both the parts and the machine.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email